International Partner Search

Innovation & Technology Offer

High-temperature protection coating with built-in thermal sensor

Country of Origin: Switzerland

Reference Number: TOCH20200205001

Publication Date: 17 February 2020

Summary

A Swiss school of technology offers a high-temperature protection coating with a built-in thermal sensor. The new functional coating warns against thermal loads by irreversibly changing its colour. The coating can be used on components, which are prone to material degradation from thermal loads, in order to make inspections fast and easy. Components comprise turbines, boilers, pipes or bearings which operate in harsh. Type of partnership: licensing agreement.

Description

Background:

Indicating local spots of thermal load on large-scale components is challenging, because the area of interest may not be accessible by electronic sensors or the complete coverage of the area may require an excessive number of sensors.

Solution of the Swiss school of technology:

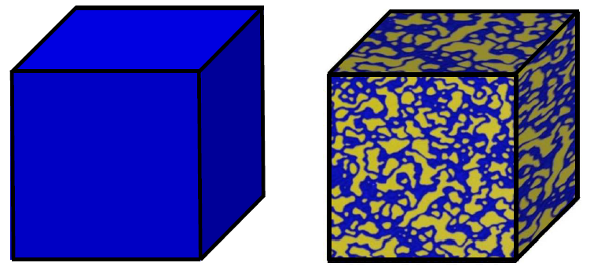

The hardware of interest can be covered with a new functional coating, which will indicate the thermal history. First, a layer of TiN (titanium nitride) is applied, then an ultrathin layer of TiAlN (titanium aluminium nitride). When exposed to high temperatures (> 500°C) the TiAlN decomposes into TiN-rich and AlN domains (fig.1.) The decomposition is accompanied by a blue-shift in the absorption spectrum, which is visible by eye (fig. 2). Proof-of-concept experiments have been carried out. Additional benefits of the coating are wear and oxidation resistance, which makes it applicable to harsh conditions.

Fig 1. (left) homogeneous structure within the coating, (right) an excessive thermal load causes the decomposition of the TiAlN layer

Fig 2. the photo shows top to bottom three metal sheets with 70 nm, 43 nm and 23 nm TiAlN on TiN, respectively. The sheets have been exposed to 25°C (left) to 900°C (right). Beyond 500°C (dotted line) the thermal sensor visibly starts responding. The onset can be tuned.

Desired cooperation:

A licensing partner is sought who already manufactures machine components for harsh environments and who would like to enhance the product performance by adding a functionalized protection coating.

Potential products and applications:

The coating can be applied to turbines, turbine blades, boilers, pipes or bearings, which operate in harsh conditions and suffer from thermal loads, or likewise applications.

Advantages and Innovations

Operating range: the coating is ultrathin and extremely hard. It is resistant to wear and oxidation and protects up to 900°C.

Functionalization: the coating indicates thermal loads locally. During inspection it will be obvious which part of the component has been exposed to a thermal load, making inspections inspections fast and easy. Qualitative inspections can be made by eye, quantitative inspection by spectrometer.

Stage Of Development

Available for demonstration

Requested partner

The specific area of activity of the partner:

Manufacturer of machines / machine components (i.e turbines, turbine blades, boilers, pipes or bearings) for harsh environments

The tasks to be performed by the partner sought:

The partner proposes a business plan and/or implementation plan based on this invention and takes a license with the purpose of commercializing the invention.

Cooperation offer is closed for requests