International Partner Search

Innovation & Technology Offer

Efficient preparation and purification of the amino acid L-Tryptophan.

Country of Origin: Germany

Reference Number: TODE20180910001

Publication Date: 10 September 2018

Summary

A German university has developed a novel process to purify the amino acid L-Tryptophan, an additive in the feed and food supplement industry or raw material for the pharmaceutical industry. The process avoids the usage of acids and bases and uses specific alcohols in a cooling process instead. The university offers a license and/or a technical cooperation agreement.

Description

L-Tryptophan is an essential amino acid, which e.g. is used as dietary supplement, as food additive and as a pharmaceutical. The synthesis is possible in different ways. A prominent method for its preparation is the biotechnological fermentation with microorganisms. The prepared raw Tryptophan still includes impurities and therefore has to be purified before it can be used in the described areas. Known purification methods use the crystallisation effect of Tryptophan under change in the pH. In order to use this method, the fermentation broth has first to be treated with sulfuric acid to reach a pH below 2 and then the pH has to be raised rapidly by using e.g. sodium hydroxide to end at a pH around 6-8.

This conventional process has several disadvantages. Besides the loss of acid and base in high volumes, the usage and combination of both come along with corrosive processes. Therefore, the construction and equipment has to be selected with respect to this. The corresponding salts have to be removed in washing steps from the crystals, too.

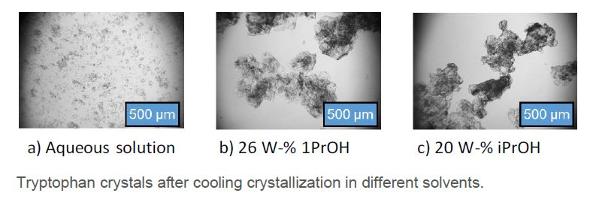

A German university now developed a novel process that avoids the usage of acids and bases and uses specific alcohols in a cooling process instead. The proof of principle has been shown in a batch and also continuous processes. The combination of process steps as solving of the product, reduction of solvent and cooling of the broth can be varied and shows different effects of the characteristics and accessible yields of Tryptophan.

The university offers a license agreement to biotechnical, chemical or pharmaceutical companies interested in applying the process. In order to upscale the invention to an industrial level or meet the respective requirements of a sector the university also offers a technical cooperation agreement.

Advantages and Innovations

The main innovation in comparison to current procedures lies in the gentler production compared to excessive use of acids and bases. The procedure allows for a longer use of installations and no mandatory use of stainless steel fermenters. This leads to a drastic reduction of resource requirements. In addition, the yields of an optimized process are likely to be better than the conventional ones.

Other advantages:

• Easy handling of solvents

• Up to 90% recovery

• Reduction of waste material

• Varied crystals under specific conditions

Stage Of Development

Under development/lab tested

Stage Of Development Comment

proof of function

Requested partner

The university offers a license agreement to implement the new process. The companies addressed come primarily from the biotechnical or chemical industry. The amino acid is used in the feed or food supplement industry. Perhaps also the pharmaceutical industry (depending on the required degree of purity) might be interested.

Since the requirements are higher depending on the industry sector the university also offers a technological cooperation agreement. And because previous research has only taken place on a smaller scale an upstreaming to larger volumes can and should of course be optimized.

Cooperation offer is closed for requests