International Partner Search

Innovation & Technology Offer

Optical quality monitoring system for the production process of industrial chains - continuous telecentric imaging of each individual chain link ensuring product quality and technical safety

Country of Origin: Germany

Reference Number: TODE20180920002

Publication Date: 20 September 2018

Summary

A German research team specialized in industrial process optimization has developed an optical quality monitoring system for the production process of industrial chains. All ascertainable dimensions of each chain link are continuously recorded by two cameras and all relevant values such as pitch and true link length are subsequently calculated. The highly precise system allows continuous quality control of the entire chain production. Team seeks partners for technical cooperation or licensing.

Description

The invention refers to the quality control of the manufacturing process of industrial chains (e.g. round steel chains, conveyor chains, heat resistant / stainless steel chains, hoist/ sling/pump/sprocket chains, etc). Looking at consecutive links of a chain in the manufacturing process, both “ends” of a link are always obscured by the “ends” of the preceding and the successive link. Thus, technical relevant dimensions such as the effective length of a chain link cannot immediately be determined during the production.

Up until now randomly taken samples are controlled by tactile measurement through gauging tools.

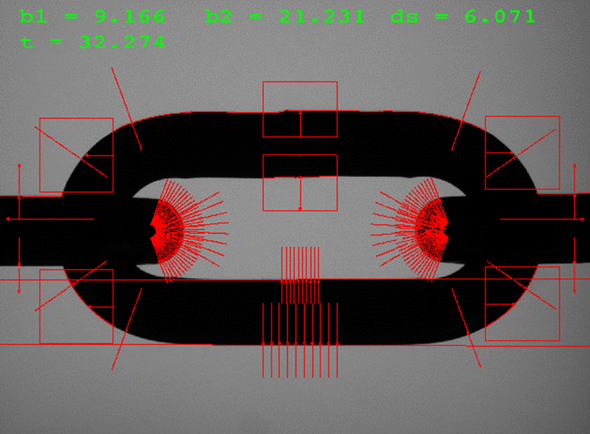

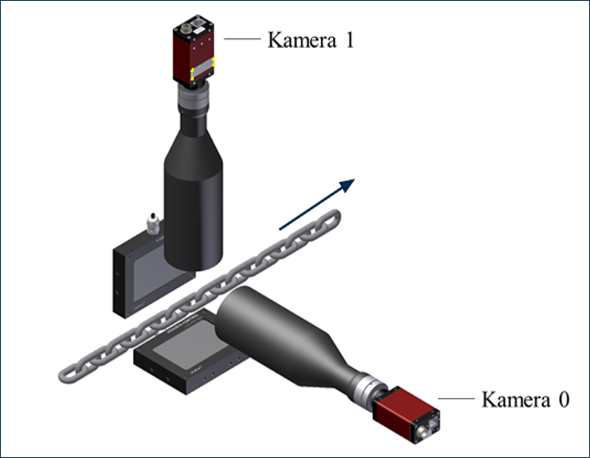

The proposed optical solution solves this problem. Two cameras positioned at an angle of 90° to each other and placed at the appropriate quality control spot in the production, are measuring continuously all visually recordable dimensions of each link through telecentric imaging.

From the recorded data, auxiliary variables are derived and initially, nonvisible values, such as the pitch/spacing/effective length of the chain links are subsequently calculated. Deviations from the predetermined dimensions can be identified and corrected immediately. Thus, the innovative optical monitoring system allows the continuous quality control of each link and therefore of the entire chain production.

The developer is looking for engineering companies and developers or provider of process monitoring systems as well as manufacturers of industrial chains. The prototype needs to be further developed to a marketable product and adapted to the respective monitoring application. The patent can be purchased. Moreover, licensing is also possible.

Advantages and Innovations

There are no alternative automated continuous quality monitoring methods available, so far only random sampling is carried out, thus leading to an inconsistent quality control. Whereas, the proposed telecentric imaging allows continuous imaging and recording of the dimensions of each link and generates all necessary values for the detection of deviations.

The inspection of each link in the manufacturing process allows immediate response in the case of deviations and the respective adjustment of the link manufacturing tools / bending and welding tools.

The optical system offers fast and highly reliable quality control of chains, thus ensuring product safety.

It is adaptable to different chain types and sizes.

Stage Of Development

Available for demonstration

Requested partner

The researchers are not only looking for engineering companies and developers or providers of process monitoring systems but also manufacturers of industrial chains. The existing prototype needs to be further developed to a marketable product and adapted to the respective monitoring application. Therefore, possible cooperation types include not only technical cooperation for joint product development but also the purchasing of the patent or licensing would be an option.

Cooperation offer is closed for requests