International Partner Search

Innovation & Technology Offer

Thin sheets of CrMnNi austenitic stainless steel

Country of Origin: Germany

Reference Number: TODE20190924001

Publication Date: 12 November 2019

Summary

A German university has invented a process for the production of sheets and strips, in particular thin sheets from CrMnNi austenitic stainless steel on an industrial scale, saving costs and material compared to existing processes. Thin sheets are suitable for the production of heat exchangers and other corrosively stressed components. Sought-after partners are those, which are interested in a licensing agreement or a technical cooperation agreement.

Description

A university in Germany has developed a manufacturing process for sheets and strips, but especially thin sheet, which has significant advantages over existing methods.

The partial substitution of nickel by manganese and nitrogen (X3Cr17Mn8Ni4MoN steel) results in a highly cold-formable steel with increased strength. This metastable austenitic steel has a pronounced TRIP/TWIP effect at and above room temperature. Furthermore, this steel exhibits an anomaly pronounced elongation in the temperature range from 40 °C to 150 °C with a simultaneous increase in tensile strength.

TRIP:

Transformation-induced plasticity

Austenite transforms into α- martensite induced by deformation during cold forming.

TWIP:

Twinning induced plasticity

Twinning and the formation of ε-martensite during cold forming.

The reduction in the proportion of nickel leads to a significant cost savings while lower material consumption.

The university is searching for industry users of the patent that have an interest in licensing the existing IP (intellectual property). Besides the licensing, the technology provider also provides further technical support for the implementation of the knowledge within the institution.

Furthermore, potential users are sought which will test the steel in their environment under a technical cooperation agreement.

Advantages and Innovations

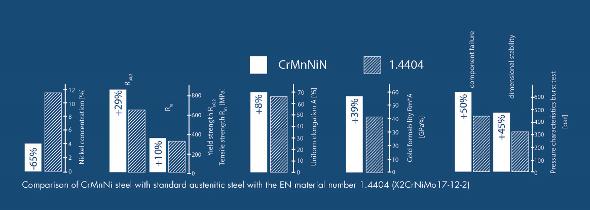

The economic advantage over other stainless steels is found in the resource efficiency. The saving of alloy costs is due to the higher than 50% reduced use of nickel compared to steel 1.4301 or 1.4404. The improved cold forming properties make it possible to reduce the number of cold forming stages in the production of thin sheets and foils up to 13μm. The higher strength of the material provides a reduction of the material usage, making lightweight components even thinner and lighter. The corrosion resistance of CrMnNiN steel are improved with regard to pitting corrosion.

Stage Of Development

Available for demonstration

Requested partner

The university searches industrial partners, that have expertise in melting, as well as hot and cold forming in order to carry out an IP transfer. Besides, potential users of the superior steel are searched that are willing to test the steel within their environment.

Cooperation offer is closed for requests