International Partner Search

Innovation & Technology Offer

Device for the efficient production of nanoparticles

Country of Origin: Spain

Reference Number: TOES20180904001

Publication Date: 17 April 2019

Summary

A Spanish research institution and a Spanish advanced technology R&D company have developed a magnetron sputtering device where a homogeneous erosion of the target is achieved and the stability and the production rate of nanoparticle flux for long periods of time are enhanced. Industrial partners manufacturers of industrial and/or lab equipment are being sought to collaborate through a patent license agreement for commercial exploitation of technology.

Description

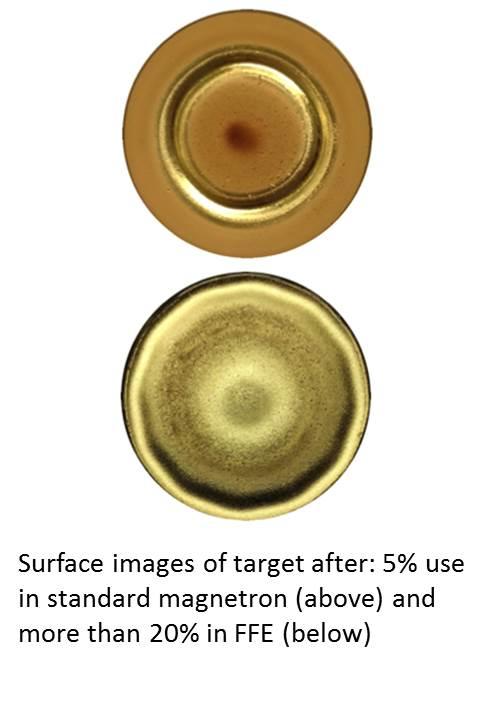

Planar magnetron sputtering is widely used in the generation and deposition of nanoclusters because of the high rate and wide area of deposition. However, the magnetron discharge plasma is not uniform so the total target utilization is only about 10% due to the narrow and deep groove erosion on the target, known as a racetrack, decreasing its lifetime.

The new device, developed by a Spanish research institution and a Spanish advanced technology R&D company, comprises two chambers. The first chamber, devoted to the generation of nanoparticles, combines an FFE magnetron with a gas aggregation source. This arrangement allows the stable production of nanoclusters or nanoparticles beam overtime improving the use of the target. The injection of other gases in this chamber, apart from the sputtering gas, increases both, the stability and the production rate of the nanoparticle flux. The second chamber is arranged for the substitution of the substrates where the nanoclusters are deposited.

Industrial partners are being sought. In particular, companies which manufacture industrial advanced technology equipment and/or lab equipment. The collaboration would involve a license agreement for commercial exploitation of the technology.

Advantages and Innovations

-The weight consumption of the target is higher with respect to that of the standard magnetron sputtering.

-The target wear is much more uniform. It avoids the formation of a narrow racetrack preventing a reduction of NP beam intensity.

-A longer use of the target is achieved. The target used in the FFE magnetron has been operated during more than 12 hours at an average power of 90 W without the need to be exchanged.

-Higher stability of the nanoparticle flux over long periods of working time.

-Nanoclusters or nanoparticles of conductive, semiconductive or insulating materials can be obtained (e.g.: Au, Ag, Cu, C; Si, SiC. Likewise, a wide range of substrates can also be used.

Stage Of Development

Available for demonstration

Stage Of Development Comment

A prototype is available

Requested partner

Industrial partners are being sought. In particular, companies which manufacture industrial advanced technology equipment and/or lab equipment. The collaboration would involve a license agreement for commercial exploitation of the technology.

Cooperation offer is closed for requests