International Partner Search

Innovation & Technology Offer

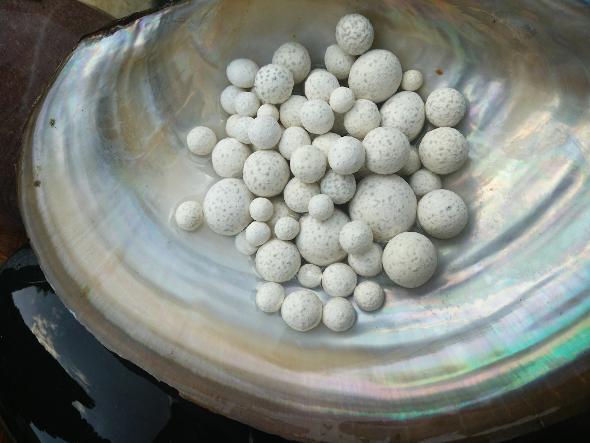

All-natural hydrophobic oil adsorbent powders and granules for environmental & industrial purposes

Country of Origin: Hungary

Reference Number: TOHU20170928001

Publication Date: 9 October 2017

Summary

A Hungarian company with an advanced technology for turning materials into hydrophobic oil adsorbent powders or granules is looking for possible business partners interested in R&D, joint venture or licesing & technology transfer. Main advantage of technolgy is multiple application: industrial filtering solutions for liquids and gases, emission control, waste management and cleaning, adsorbents, technological cleaning, capillary systems cleaning for food, seed oil, cosmetics industry.

Description

A Hungarian spin-off startup company owns a technology/original industrial process by which natural materials can be turned into products with hydrophobic oil adsorbent properties. The captured oil can be extracted and recycled, and the product can be reused several times over. These products can be developed as powders or granules with varying levels of hardness, water resistance, size, and density for diverse set of applications. Based on raw material, products can be further enhanced to inherit additional properties for heavy metal adsorption, gas adsorption, protein adsorption, and more.

The technology has two different areas of use:

1. Industrial and environmental water purification, gas capture, emission control (focus on filtering solutions)

The produced material is hydrophobic, meaning it does not absorb water or other water based fluids, does not crack in the presence of moisture. It can also be produced from widely available raw materials. Depending on the size and the set properties, it is suitable for both water (surface or settling solutions) and air filtering. The intended use is mainly to remediate surface water and soil after oil spills, also as a base material for water and air filters. With the application there are no harmful substances formed, the oil can be detached from the adsorbent and may be used as a fuel. There is no significant change in the water's pH level following the application. The technology is compact, needs little space, can be operated independently and requires no training. The production does not involve water use, it is space-saving, energy-saving, scalable, fully automated with minimal human resource requirements.

2. Cleaning industrial capillary systems (mainly in the food industry)

In food, oil, and cosmetic industry the mandatory cleaning protocols require regular production halts, outages and an intense use of chemicals. With capillary systems the oils and greasy materials are piped through tight tubes which as time goes get clogged and become useless. Cleaning or changing these parts is costly, and in both cases take considerable time and effort.

With the use of the mentioned oil adsorbent granulates (with right size and hardness) the clogging problem can be solved easily. The material can simply be injected with water flow into the oil-contaminated piping systems. This can completely clean up the greasy deposits without using detergents or disassembling, which saves a lot of time and money by lowering the time of outages. This is a cost effective, water saving, cheap and environmentally friendly treatment that requires fewer downtime. Presents great alternative for current solutions.

The company is looking for possible cooperation partners interested in joint R&D to identify further areas of use, business partners interested in joint venture or licesing & technology transfer to bring the technology to market, identify potential industries or target markets.

_result.jpg)

.jpg)

Advantages and Innovations

• Versatility: diverse, easily accessible raw materials, adaptable product properties, fine-tunable solutions

• Ecological: natural ingredients, low consumption, recycled materials, emission control, no harmful residue

• Adsorbs oils and Total Petroleum Hydrocarbon (TPH) components from liquids, surfaces, soil

• Some versions adsorb gas emissions e.g. CO2.

• Multiple application fields in various industries

• Diverse models: On its own as technology, as part of production technology, ingredient/additive to materials, ready to use product range, etc.

• Fully automatized, scalable production technology

• Supporting technical tools, on-going R&D

Stage Of Development

Prototype available for demonstration

Requested partner

- Industrial partners engaged in construction or environmental sectors. Role: To license the technology to make the end-materials individually in a defined field/region.

- Industrial partners interested in R&D cooperation. Role: To define where and how research could be done to add value to technology or scope of use.

- Investors interested in joint venture partnerships who would act as technology owners in a given region.

Cooperation offer is closed for requests