International Partner Search

Innovation & Technology Offer

Self-learning, deep learning-based machine vision solution for fully automatic products inspection.

Country of Origin: Italy

Reference Number: TOIT20200825001

Publication Date: 21 September 2020

Summary

An Italian innovative firm has developed an automatic "zero setup" system to control every kind of product. The solution is especially fit for food and non-food products analysis and it doesn't need to be programmed as it contains self-grading and self-learning features. The SME is interested in technical cooperation deals with partners specialized in the automation sector to propose integrated systems to end users or in commercial deals with technical assistance with end users directly.

Description

An Italian innovative firm has developed an automatic "zero setup" system to control every kind of product. The solution is especially fit for food and non-food products analysis and it doesn't need to be programmed as it contains self-grading and self-learning features. The SME is looking for technical partners specialized in the automation sector to propose integrated systems to end users or is looking for end users directly for commercial deals with technical assistance.

The error margin, thanks to the use of such a system is reduced to zero. This is thanks to its exclusive human-like ability to evaluate the particularities of each element by accurately distinguishing acceptable anomalies from defects.

It works automatically taking advantage of its built-in self-grading and self-learning procedures, therefore it doesn't need to be programmed.

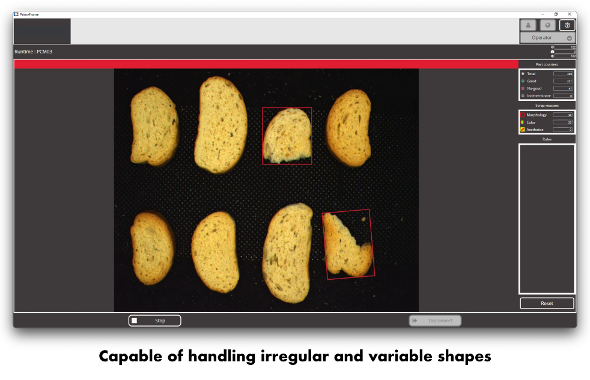

The company developed an industrial vision solution for quality control directly on the production line, capable of completely replacing human work, bringing the effectiveness and performance of supervision to new levels. Its performance is constant, repeatable and objective on 100% of production.

The proposed solution does not require configurations or settings and can be customized at any time to adapt to clients' tolerance meter.

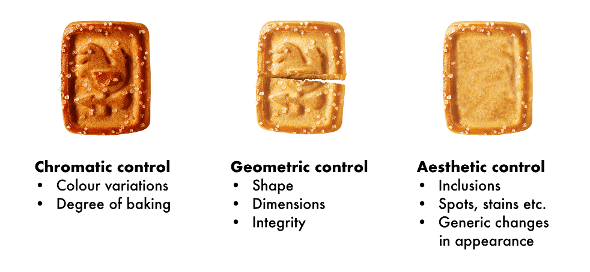

The system performs three categories of check in-line:

- Morphological, for detection of anomalies of shape and size, breakages, deformations, missing pieces, etc.

- Chromatic, for detection of color variations, cooking errors, composition anomalies, etc.

- Aesthetic, for detection of imperfections whatever their appearance or size.

Thanks to deep learning, the natural variations of the objects do not interfere with the inspection, focused on the detection of anomalous details not known a priori.

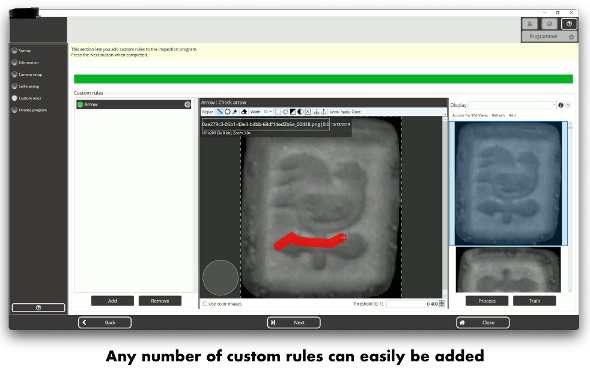

Furthermore, the flexible approach of the system allows customers to modify, if necessary, the severity of the judgments relating to the three main evaluation criteria (morphology, color, and aesthetic appearance) as well as manually adding control rules that will integrate with those that form the system automatisms. This does not translate into an overlap of different and potentially conflicting rules: the system is in fact able to apply the new cascade rules, running a fluid "selection of the selection" in order to optimize the effectiveness of the inspection.

Each additional rule allows the client to teach the system, through supervised training, to recognize specific details or defects of the concerned product. In this way it will be able to:

- Detect the presence and quantity of these details or defects;

- Get the degree of integrity of these parts;

- Evaluate the severity index of these defects.

Moreover, the solution can be improved in its search for anomalies by extending the inspection to a plurality of senses, more developed than human ones. To the two-dimensional vision of the object, which allows its morphological, chromatic and aesthetic control, it is possible to combine 3D vision, when the analysis of shape alterations requires third dimension, and hyperspectral vision, which allows the detection of chemical alterations in the element. Each of these "senses" can be implemented in the system individually or together with others, to offer a more complete and detailed analysis.

Some examples of productions that can benefit from this system are:

- Bakery products: biscuits - sweets - cakes - bread - crackers - pastry, etc.

- Frozen products: pizza - semi-finished meat and fish - stuffed and breaded foods, etc.

- Sugar confectionery: chocolate - pralines - candies - jellies - confetti - pastilles, etc.

- Various foods: fruit - vegetables - cheese - eggs - snacks, etc.

- Drugs: pills - capsules - vials - blister packs, etc.

- Other products: metal and plastic parts - die-casted and molded parts - PCBs, etc.

Advantages and Innovations

With its "zero setup" technology, the proposed solution is able to independently undertake the observation of production elements directly on the line. Having acquired the basic data, the system starts the proprietary auto-classification and, subsequently, auto-learning processes necessary to effectively implement its assessment. When fully operational, the system works by exploiting the unsupervised learning method, using self-created knowledge thanks to exclusive self-grading and self-learning procedures.

Where a standard system would stop working or would make a mistake because of its incapacity to distinguish a natural variation from a defect, the proposed solution applies built-in customizable tolerance criteria, drastically reducing the number of false rejects.

The inspection system, thanks to its self-learning and self-grading qualities, does not require the coding of all possible anomalies in instructions for the machine, therefore it can be fully flexible to adapt to any given need, going way beyond any other existing system.

What makes this solution surprisingly superior to a human's performance is its ability to:

- Take advantage of its proprietary technology to learn independently, applying the acquired knowledge to the quality inspection of products;

- Accurately distinguish product variations, ensuring precision in the exclusion of defective elements and tolerance for acceptable anomalies;

- Improve its specific performances, through personalization and “safe improvement on-demand” strategies that allow a global improvement.

But what really makes this system not comparable to a human being is its ability to:

- Inspect each element impartially, without giving in to subjective evaluations;

- Carry out an uninterrupted check, with a performance effectiveness not subject to the normal drops in results typical of the human being;

- Keep the rhythm and quality of the results constant, without distraction errors.

Stage Of Development

Already on the market

Requested partner

The company is looking for:

1. technical partners operating in the automation sector (especially for the food one) willing to bring an integrated solution to the final client/end user. Technical cooperation agreements are sought in this case.

2. end users coming from the food sector willing to implement such a solution in their production process. Commercial agreements with technical assistance are sought in this case.

Cooperation offer is closed for requests