International Partner Search

Innovation & Technology Offer

Japanese company developed anti-loosening bolt technology offered under licensing agreement

Country of Origin: Japan

Reference Number: TOJP20190703001

Publication Date: 18 July 2019

Summary

A Japanese company specialized in the manufacturing of thread rolling machinery is looking for partners in the EU to license out their anti-loosening bolt technology which is the only one of its kind in the industry. The technology has the potential to vastly reduce maintenance needs and increase safety. Therefore, the Japanese company would like to have a mutually beneficial license agreement with EU partners.

Description

A Japanese company established in 1939 that produces thread rolling machines is looking to license out their anti-loosening bolt technology which provides a loosening-resistant alternative to standard bolts currently on the market. The bolt prevents excessive loosening that occurs due to factors such as vibration, which is a common issue with standard bolts leading to them requiring a large amount of maintenance. This constant need for upkeep leads to a higher chance of human errors.

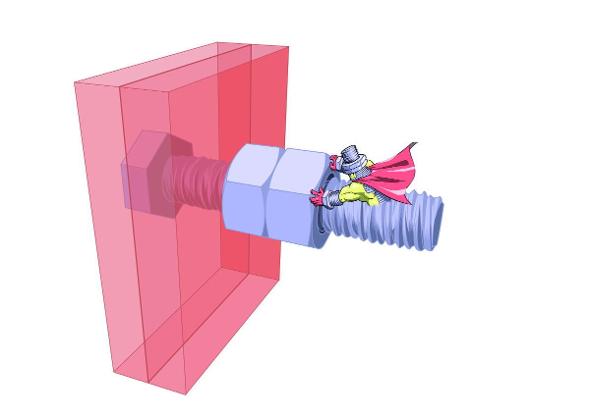

Usage of the anti-loosening bolts therefore leads to increased safety due to the decreased need for maintenance and a lower chance of failure compared to pre-existing anti-loosening fasteners which work to prevent the reverse rotation of the nut through friction. Once the loosening forces exceed the friction forces, regularly used bolts start to loosen, which creates the need for maintenance. The anti-loosening bolt prevents this due to its design as a dual-thread, mechanically-locked bolt that fastens with two nuts, each with a different pitch. The bolt is designed for repeated use and comes in a wide variety of forms to meet various application needs.

The two nuts have different helical paths, and because they move along the same bolt shaft it has the ability to resist loosening even under severe vibration and shock. The inner nut and outer nut travel along two distinct, separate, helix angles causing them to move at different speeds relative to the bolt shaft. The inner nut travels faster than the outer nut and when vibration occurs the slower traveling outer nut prevents the inner nut from loosening.

The rate of movement for each nut is pre-set by its pitch, creating the mechanical lock between the two nuts. The locking effect that is made between the two nuts can easily be released by loosening or removing the outer nut, leaving the inner nut to turn freely. The bolt is designed to have comparable tensile strength and fatigue strength to that of a generic single helix bolt of equal nominal diameter.

It took the company 14 years to develop the dies that produce the anti-loosening bolt, and they can be used with existing thread rolling machines. Therefore, the Japanese company is looking for bolts or parts manufacturers in the EU with which they can engage in a license agreement. The Japanese company will then supply the EU partner with their form-rolling dies. The Japanese company offers to EU partners to proactively support them with dedicated guidance on the production process and by providing training on how to produce the bolts.

Advantages and Innovations

The anti-loosening bolt technology created by the Japanese company is currently the only dual thread, double helix, and self-locking fastening system in the industry. Therefore, the technology creates the following advantages in its usage compared to prevailing products:

- The bolts are produced using rolled threads rather than cut threads, this leads to lower production costs creating a cost-advantage compared to the average market-price.

- Although it uses a new technology, it has the same reliability and durability of a regular high-quality bolt, proven by their acquirement of ISO 16130 which implies the dynamic testing of the locking behaviour of the bolted connections under transverse loading conditions (vibration tests).

- Potential to vastly reduce the need for maintenance and labour hours spent on upkeep, while simultaneously reducing the potential for human errors.

Furthermore, another convenience is that despite its anti-loosening design, the bolts are very easy to loosen when necessary.

Stage Of Development

Already on the market

Stage Of Development Comment

The company regularly invests in R&D with the aim of reducing the production costs of their technology and making the bolts’ manufacturing process cheaper. They are currently working on an improved version which is ‘available for demonstration’, the initial version is already on the market.

Requested partner

The potential partner should be a manufacturer in the EU interested to license a new technology and implement it in its bolts’ manufacturing process. They should have knowledge of and connections to sectors in which this technology can make a difference with regards to safety and maintenance, for example infrastructure, transportation, machinery, equipment, electronics, etc. The ideal partner would be willing to use the form-rolling dies provided by the Japanese company to produce the bolts.

Cooperation offer is closed for requests