International Partner Search

Innovation & Technology Offer

World's only PPC (plant protein composite) bio-ink and 3D printed bioscaffold

Country of Origin: Singapore

Reference Number: TOSG20190619001

Publication Date: 19 June 2019

Summary

A Singapore SME has developed the world's first and only PPC (plant protein composite) bio-ink and 3D printed bioscaffold, one of the key components needed for regenerative medicine, tissue engineering, cancer research and 3D cell culture applications. The Singapore SME is seeking licensing and commercial partnerships with technical assistance with MNEs or SMEs of all sizes.

Description

Compared to conventional fabrication methods, 3D bioprinting is an increasingly popular method of bioscaffold fabrication because of its reproducibility, better control of pore sizes, morphology and matrix porosity. However, poor printability, cell viability, high cost and issues associated with animal protein-based bio-inks continue to plague and limit 3D bioprinting applications.

The Singapore health-focus SME that extracts health from nature has developed the world's only plant-derived bio-ink through extracting and purifying plant proteins from food processing byproducts such as spent grains (e.g. corn, malt, barley).

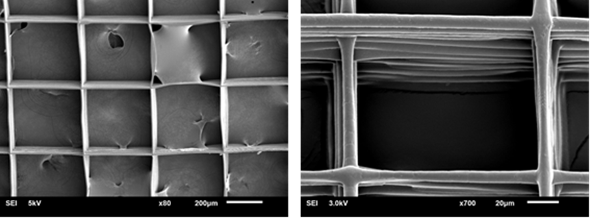

The plant proteins are formulated with synthetic polymers such as polycaprolactone (PCL) to create a uniquely first PPC bio-ink. Proven to be printable, the PPC bio-ink may be further customised in terms of viscosity, mechanical strength and biodegradation rate to meet the requirements of different 3D bio-printers. In addition, the bio-ink's natural bioactive properties make it highly conducive for cell growth while being sustainable and cost-efficient.

Together with its PPC bio-ink, the Singapore company has also developed a novel electrohydrodynamic jetting (EHDJ) scaffold printing methodology, which enables the precise, 3D printing of PPC bioscaffolds featuring multi-layers, a large surface area and small, controllable pore sizes of up to sub-micron scale with porosity of >90%. The PPC bioscaffold has been demonstrated to enhance cell attachment and proliferation, and also feature a tunable biodegradation profile that can be monitored in vivo, in real time and non-invasively.

In particular, the encapsulation properties of the PPC bio-ink allows encapsulated bioactives to be released in a controlled manner as the bioscaffold biodegrades, making it ideal for therapeutic applications such as advanced wound dressings.

With high customisability, the potential applications of 3D printed bioscaffolds include:

- Therapeutic applications e.g. wound dressing with controlled-release of medicine embedded in the scaffold

- Tissue engineering applications

- Regenerative medicine applications

- 3D cell cultures for drug discovery and development

- Tumour tissue model for cancer research

The Singapore SME seeks the following types of partnerships with MNEs or SMEs of all sizes:

i) Licensing agreement where the partner could license the technology and further develop it to introduce it to its customers.

ii) Commercial agreement with technical assistance where the Singapore SME would provide support in the bioprinting of 3D scaffolds.

Advantages and Innovations

The company's PPC bio-ink together with its proprietary EHDJ methodology and 3D printed PPC bioscaffolds have the following advantages:

- Customisable scaffold design and diverse structural fabrications in accordance to required specifications for different biomedical applications

- Tunable biodegradation profile with real-time, non-invasive in-vivo monitoring

- Cytocompatible

- Batch to batch reproducibility

- Natural bioactive properties enhance cell affinity and proliferation

- Encapsulation properties allow the controlled release of encapsulated bioactives

The sustainable method involving the reclamation and purification of plant proteins opens up an alternate source of natural proteins to animal derived proteins, without the associated issues of high cost, risk of animal disease transmission and batch to batch variability.

This faster, greener and more efficient technology is the first to market, offering additional advantages such as high customisability, natural bioactive properties, batch to batch reproducibility and real-time degradation monitoring.

Stage Of Development

Already on the market

Stage Of Development Comment

Ready for the market and commercialisation.

Requested partner

The Singapore SME is interested in licensing or commercial agreements with technical assistance with the following types of partners that can be MNEs or SMEs of all sizes:

- Bioprinting companies that need cost-efficient and customisable bio-ink for different bioprinting applications

- Tissue engineering, regenerative medicine companies that need customisable, built-to-specs 3D-printed bioscaffolds

- Research institutes, clinical research, pharmaceutical R&D organisations that need standard 3D bioscaffolds or customised 3D-printed bioscaffolds for disease modelling, 3D cell culture for drug discovery and development

Cooperation offer is closed for requests