International Partner Search

Innovation & Technology Offer

A UK SME that has developed a concept technology for smart structural adhesives seeks manufacturing, R&D or technical partners

Country of Origin: United Kingdom

Reference Number: TOUK20180905001

Publication Date: 5 September 2018

Summary

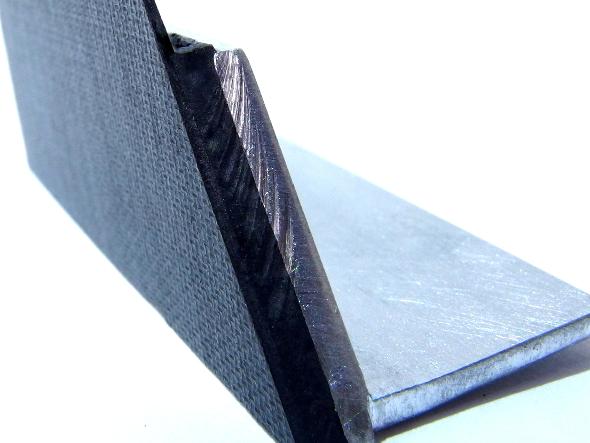

This UK company are developing a novel smart adhesive offering in-situ monitoring of bonded joint performance. End users will be able to assess in real-time a bonded joint's stress, load or environment. This technology may also provide information on structural health; checking a bond at manufacture or seeing if there has been damage in use. The company seeks an adhesives manufacturer or end user for cooperative development under either a research or technical co-operation agreement.

Description

The UK company which was established in 2014. It is a research & development enterprise born out of the University of Cambridge, with the mission of bringing to the market innovative solutions in the field of advanced materials, such as nano carbons, metals and polymers.

The company is currently developing a smart adhesive technology that will provide information on a bonded joint through simple electrical resistance testing. The technology has been experimentally validated to show a change in resistance in response to mechanical and environmental changes. The adhesive may also give information on the structural health on the bond and identify if any permanent damage has occurred.

The smart adhesive offers a greater understanding of how a bonded joint is performing. This type of information will allow end users to make informed decisions regarding a bonded structure’s health and operation. This will lead to safer structures with less failures as the adhesive will indicate when safe operating conditions have been exceeded or when a joint replacement is required.

This technology is currently at TRL3 (technology readiness level) and more development is required to bring this innovative technology to market. The company is looking for either a research co-operation agreement with an adhesive development company – target: TRL6 (technology readiness level). Joint development; where the company provide the adhesive concept and the adhesive company provide formulation expertise.Joiint testing; the company will validate the sensing element of the adhesive and the adhesive company will provide mechanical testing.Approach to market will be through the adhesive company’s portfolio.If the product gets to market, further cooperation will be required between the company and the adhesive company for future manufacturing. Validation of the adhesive will be through an end user following a research agreement co-operation.

Alternatively the company is seeking technical co-operation agreements wiith an end user – target: TRL8 (technology readiness level) The company will solely develop and formulate the adhesive product and will perform testing of sensing and mechanical ability.The end user will validate the technology and provide feed back to the company to improve the product. This technical cooperation will require the end user to provide the funding for the development. However, this will provide the most direct and clear route to market due to the feedback loop that will be formed between the company and the end user. The end user will have some benefits of the technology cooperation, such as exclusivity or joint ownership of the technology.

Advantages and Innovations

The initial smart adhesive product has been formulated with some properties experimentally verified by an external academic institute.

This is a ground breaking product which has only one other competitor which does not operate identically, uses different test methods and is far more costly than the company's product. There are numerous opportunities for significant development with the adhesive product with appropriate partners.

The technology has already identified 3 major application areas:

• In situ sensor for structures and systems

• bond fatigue measurement

The concept is to use this adhesive to provide a quick method of testing how well an adhesive bonded joint has been made, in a production line for example. A simple resistance test (potentially coupled with some mechanical stress on the bond) should provide information to allow the operator or automated software whether a bond has been made to full strength or if there are defects or poor adhesion. This approach may provide a non- destructive, simple and cheap test of a bonds strength that could be performed quickly. The test (if speedy enough) may also be placed within the production line, to allow 100% of the boned joints in the population to be tested, rather than sampling the population.

Stage Of Development

Under development/lab tested

Requested partner

The company are seeking a partner that has the means to develop and implement this technology in an application or a need for a product which this technology will fit and add value to.

Cooperation offer is closed for requests