International Partner Search

Innovation & Technology Offer

A completely novel CCU (carbon capture and utilisation) technology that turns large parts of the chemical industry carbon-neutral or carbon-negative

Country of Origin: United Kingdom

Reference Number: TOUK20190711001

Publication Date: 11 July 2019

Summary

A small UK company has designed and patented a device that turns CCU thermodynamically favourable. Methane, CO2 and air react in a coupled device of a solid oxide fuel cell and electrolysis cell. Financiers and large corporates are sought to fund the building of a demonstrator. Technical co-operation is sought with industry and academia for the demonstrator, around fuel cell chemistry and gas chromatography.

Description

The chemical industry worldwide makes up 10% of the global energy demand, and it is responsible for 5.5% of global CO2 emissions.

As the industry is so large and complex, the progress in meeting various climate-related targets seems to be much slower than in the sector of transport for example. Although new technologies are being proposed specifically for the chemical industry, there is no agreement over how the targets will be met exactly.

As of now, the CCS (carbon capture and storage) is only economically viable in the vicinity of certain mineral deposits that bind CO2. CHP (combined heat and power generation) is another accepted method to save energy. A lot more needs to be done though as the chemical industry is not decreasing, it’s growing.

Another method, with large unexploited potential is CCU (carbon capture and utilisation). CO2 is being used as a raw material for making new products. This can be done via syngas for example, a common feedstock in the chemical industry, a mix of carbon monoxide, hydrogen, and smaller amounts of carbon dioxide, oxygen and other gases. Using well known processes, synthetic fuels and polymers can be made.

Splitting CO2 is thermodynamically very unfavourable. Tremendous amounts of energy are consumed worldwide. Usually, steam is being reacted with CO2. There is a search going on for more favourable processes, and methane has been shown to be a good candidate, but still, high temperature is needed in some patented processes, and also high pressure in another.

A small UK chemical company with decades of experience in the industry, has modelled and designed a device that makes the reaction thermodynamically favourable and sustainable. A positive search report has been returned to the patent application.

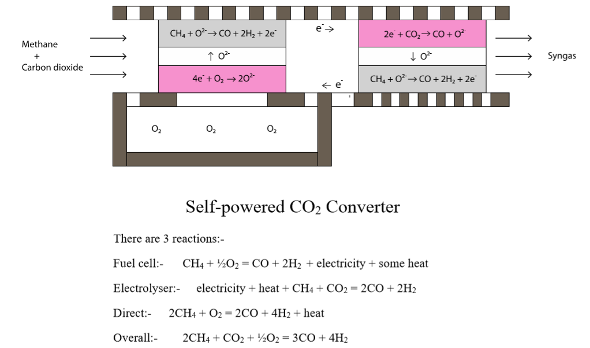

The design of the device is summarised in the picture. It reacts carbon dioxide with methane and air to form syngas. This reactor requires no additional heat or electricity, as the energy is derived from the chemical energy in the methane.

The technology is based on solid oxide cells which operate at temperatures above 500°C. It combines a fuel cell which partially oxidises the methane to syngas, and generates electricity, with an electrolyser which reacts carbon dioxide with methane to produce more syngas, and consumes electricity. The thermodynamics are very favourable, so that even if the fuel cells and electrolysers only operate at 50% efficiency, there is more than sufficient voltage from the fuel cell to drive the electrolyser reaction. Solid oxide cells typically operate at better than 70% efficiency.

Combining fuel cells with electrolysers is a potentially complex process because of the required electrical connections, heat input, gas ducting requirements, and problems with carbon deposition. The UK company has a relatively simple solution to this complex problem, described in the patent.

As the components of the device are readily available, the company now wishes to progress fast with a demonstrator. Financing agreements are being pursued, and technical co-operation with academia or industry with expertise in SOFC (solid oxide fuel cell) ceramics, and chromatographic analysis of influx and outflux gases.

Advantages and Innovations

It is the first time that a coupled fuel cell-electrolytic device is being used in CCU.

The design incorporates technical novelties such as:

• methane, carbon dioxide and the reaction products are mixed together in a single gas zone, with only the oxygen (or air) ducted separately.

• there is a direct connection between each fuel cell(s) and each electrolyser(s). This provides an electrical connection, and also a thermal one allowing heat transfer from exothermic anode reactions to endothermic cathode reactions.

• oxygen is allowed to bleed directly from the oxygen conduit into the reaction zone. This provides heat, but also helps to prevent carbon deposition.

The advantage is of course that large parts of the chemical industry will be turned carbon-neutral or carbon-negative.

Stage Of Development

Concept stage

Requested partner

Type of partner sought: industry and academia.

Specific role of partner sought: the finance industry or large chemicals businesses are invited to fund the building of the demonstrator. Industrial or academic co-operators are needed for the demonstrator, with particular skills in SOFC chemistry and/or gas chromatography.

Cooperation offer is closed for requests