International Partner Search

Innovation & Technology Offer

Italian start-up offers an innovative technology for the reliable and economic recovery of raw material from different wastes while capturing carbon dioxide.

Country of Origin: Italy

Reference Number: TOIT20210722001

Publication Date: 22 July 2021

Summary

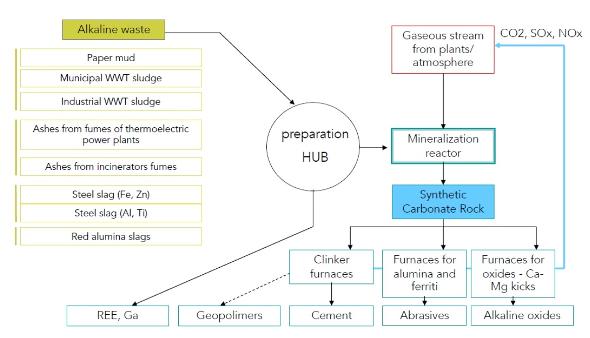

An Italian company developing sustainable technologies for circular economy is seeking partners for a research cooperation. It offers a solution based on the use of alkaline waste for the mineralization of carbon dioxide (CO2), reducing both investment and operating costs. It can be applied in several sectors, such as: •civil and industrial wastewater treatment plants; •waste incinerators; •iron and steel mills; •plastic industries; •cement industries; •aluminum production.

Description

This Italian engineering company offers a wide range of technology in waste material recovery and gas treatment, with the aim of providing solutions for the efficient management of resources and clean energy provision.

Carbon capture storage and sustainable raw materials are crucial to reach the European Green Deal objectives. Alkaline waste is the most common industrial and civil waste. Million tonnes of waste are disposed of in landfills every year; instead, they can be part of a raw material recovery circle.

The existing most advanced technologies of carbon capture are partial-oxyfuel combustion, amine scrubbing, and calcium looping, followed by direct capture and full-oxyfuel combustion.

Currently, carbon capture is possible via CO2 mineralization, CO2 to fuel, and CO2 to chemicals.

CO2 mineralization requires a high-energy environment, as the rate of reaction between rock and bicarbonate is slow. Furthermore, to enhance CO2 dissolution, high pressure or supercritical conditions are necessary.

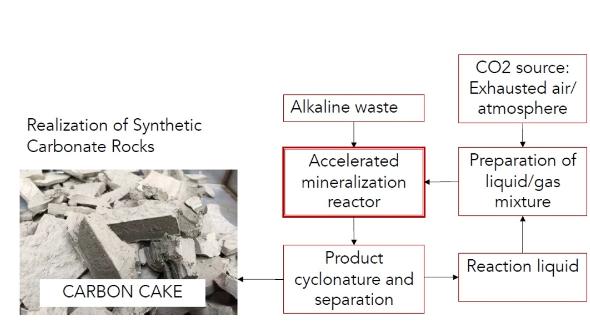

The solution developed by this start up is resilient, sustainable and scalable; it uses alkaline wastes as bases for the mineralization of CO2 and cavitation to reach supercritical conditions. The resulting calcium and magnesium carbonates (carbon cake) are then exploited as raw materials by the industries producing lime and alkaline oxides. This technology achieves high transformation rates at low temperature and pressure, reducing investment and operating costs, with a low carbon footprint.

The waste is treated by means of an accelerated mineralization reaction, based on the turbulent injection of CO2-rich gas currents into a reaction tank to form synthetic carbonate rocks.

These rocks, granulated or pulverized, would be reclassified as products, because of their chemical and physical characteristics, becoming raw materials.

The envisaged partnership is a research and cooperation agreement, to allow the Italian enterprise to pool its R&D capacities with different partners to further develop and improve its technology, benefitting all parties involved.

Advantages and Innovations

Usually, accelerated carbonation achieves CO2 uptake of 7-22% weight, depending on the mineral feedstock. Unlike other CO2 mineralization solutions, this technology achieves CO2 uptake > 85% weight.

The main innovations and advantages of this process are:

•Producing carbonate raw materials without affecting natural resources;

•Diminishing overall CO2 emissions into the atmosphere;

•Reducing the amount of waste sent to disposal;

•Creating products out of waste, enhancing environmental impact and sustainability of enterprises;

•Saving on the supply of raw materials;

•Gaining from carbon trading and production of raw materials;

•Making a profit from waste collection and recovery.

A case study has been conducted in a steel mill and the costs of this treatment proved to be extremely low: a 100,000 ton/year slags treatment plant would have a treatment cost between 10 and 15 €/ton (dry weight). Moreover, total revenues between € 50 and € 80/ton have been estimated, divided as follows:

•Revenues from carbon trading: 30 €/ton CO2 captured.

•Revenues from the sale of the raw material for kicks and clinkers: 20-40 €/ton.

•Contribution from waste disposal 20-30 €/ton.

Stage Of Development

Available for demonstration

Requested partner

Type of partners: companies, universities, research centers operating in the field of alkaline waste recovery.

Role of partners: being involved in the process of research and development, helping the Italian SME further improving its existing technology.

Cooperation offer is closed for requests