International Partner Search

Innovation & Technology Offer

A Korean company offers eco-friendly and non-toxic artificial leather manufacturing technology by a new waterborne method

Country of Origin: South Korea

Reference Number: TOKR20171101001

Publication Date: 1 November 2017

Summary

A Korean company has developed waterborne process for eco-friendly synthetic leather production without the use of VOCs (Volatile Organic Solvents), which are known to have harmful effects on human body. The innovative production process helps to achieve improved material property and reduced production cost. The company wishes to offer their production technology to corporations that are interested in artificial leather production under a commercial agreement with technical assistance.

Description

Solvents such as DMSO, DMF and DMAc have been frequently used to dissolve resin for industrial purposes. However, all those solvents are not acceptable nowadays for industrial applications due to the strengthened regulations on VOC (Volatile Organic Compounds) and toxicity. VOCs are organic chemicals that have a high vapor pressure at ordinary room temperature. Chronic exposures to VOCs are known to cause cancer and/or liver & kidney damage. Also, it may make symptoms worse for people with asthma.

Since its establishment in 2001, this Korean company has been supplying industrial machinery to many other reputable companies in the industry of paper, tissue, non-woven and chemical/non-ferrous materials.

The company has recently developed innovative ways to produce synthetic leather without the use of harmful chemicals. Every step of the manufacturing process is waterborne and Green Solvents (environmentally friendly solvents like alcohol) are employed instead of VOCs.

The company has the chemical and equipment technology to prevent the concentrating phenomenon of the fiber structure drifting on both sides when the waterborne resin is dried. In addition, the company holds the excellent surface treatment for leather called eco-friendly waterborne soil release finish technology, which is effective in stain resistance and meets the standards of artificial leather for children’s playmats.

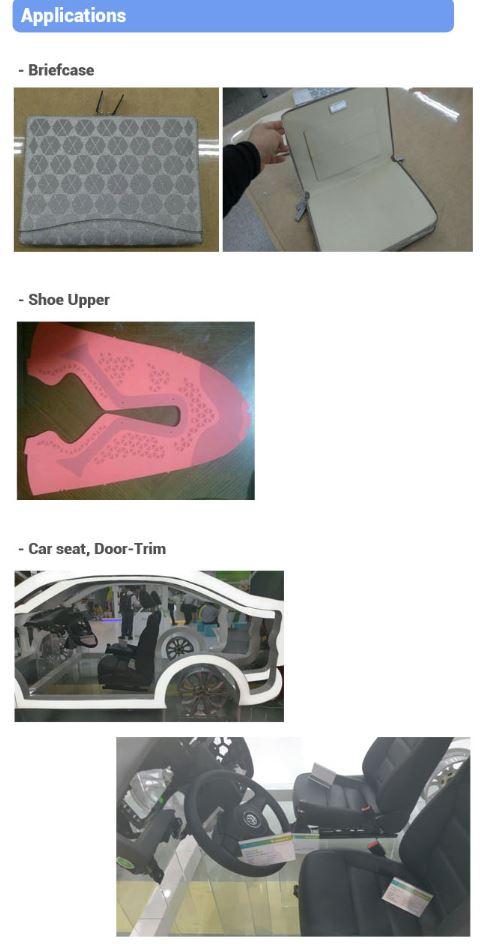

The company’s waterborne microfiber technology is also excellent in light-stability and frictional resistance. The company has water-based flame retardant technology that meets the standards of artificial leather for interior parts of automobiles and ships, and consumer goods such as briefcase, shoe sole and etc. The technology and its machine are newly developed, and the company wishes to offer the equipment and the know-how related to the technology to other leather manufacturing companies under a commercial agreement with technical assistance such as training of a technician regarding the installation and operation of the manufacturing equipment.

Advantages and Innovations

Harmful substances such as formaldehyde, benzene, toluene, ethyl benzene, xylene, styrene, and cadmium cannot be found in the artificial leather made by the company.

The dispersion stability of resin and the color development have been highly improved through the Korean company’s following activities: Designing the components and tissues of application(fabric), applying waterborne synthetic resin method (without using DMF, DMAC, DMSO) and green solvent, and using water-based toner.

The new process not only enables to achieve improved material property of finished products, but also reduced production cost by minimizing the chemical waste disposal.

Stage Of Development

Already on the market

Requested partner

- Type of partner sought:

Enterprises

- Specific area of activity of the partner:

Textile industry

- Task to be performed:

Manufacture of artificial leather

Cooperation offer is closed for requests